REFURBISHING THE NAUTILUS MINISUB

~ PAGE FOUR ~

SCROLL DOWN FOR LATEST

It's taken a long time and a lot

of hard work in my spare time to reach this point, but the shop and storage are

finally set up and work on the Nautilus Minisub is

underway again. This is my new office.

Wearing it's

rotary collar, the dusty sub rides on a wheeled carrier in the shop.

We've obtained the

shafts, bearings, seals, couplers, through-hull, and propeller shaft for the drivetrain.

Guidance control

will be achieved via medical-grade 12-volt actuators to move the rudder and

planes.

As of September 17th, 2018, I've purchased this 48 volt motor and controller

system (with potentiometer instead of a twist grip) rated at 6 hp continuous

and 16 hp for sprints of up to one minute.

I could have gone bigger and more powerful (and still can if I later

want to change the motor and controller)

but I don't believe we'll need it.

If this boat cruises in the neighborhood of 5 to 6 mph and can sprint

briefly at a top speed of, say, 10 to 12 mph; that will be about right for

performance, appearance, and spectator appeal.

And even by conservative calculations, this system should be able to

spin a 10" diameter by 10"

pitch propeller fast enough to do that and maybe more.

So, with all the major

components for the drivetrain and control system

upgrades either on our shelves or in the mail, here's the plan. (1) Assemble and water-tank test the

propulsion system and bench-test the guidance actuators. (2) Install them in the submarine using the

original through-hull stuffing boxes and shafts; repacked, of course. (3) Install all previously-removed exterior

metal plating so she looks exactly like she did during the proving tests of

1991. (4) Check and dry-test weight

& balance and adjust component (battery) position as necessary to achieve

normal CG with pilot weight in the cockpit.

(5) Launch the boat and conduct surfaced and submerged tests of the new

propulsion and guidance systems. (6)

Modify the hatch, foredeck and pilot house for lighter weight and greater ease

of access. (7) Replace the control

through-hulls with pressure-compensated units containing bearings, seals, and

packing on lathe-turned stainless steel shafts.

After the boat is running

properly, I'll "put the icing on the cake" with

exterior detailing as seen in 20,000

Leagues Under the Sea. Rakers, headlights, gills, hatches, skiff, anchors,

fairings, and about 15,000 simulated rivet heads. All that good stuff. J

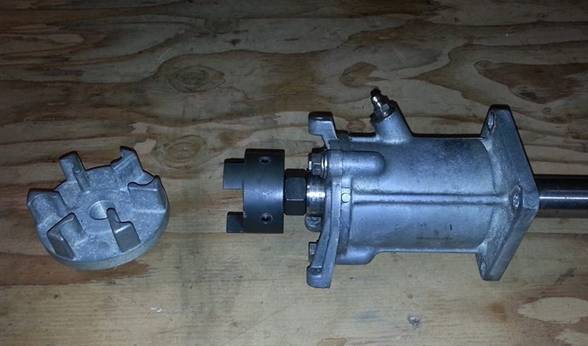

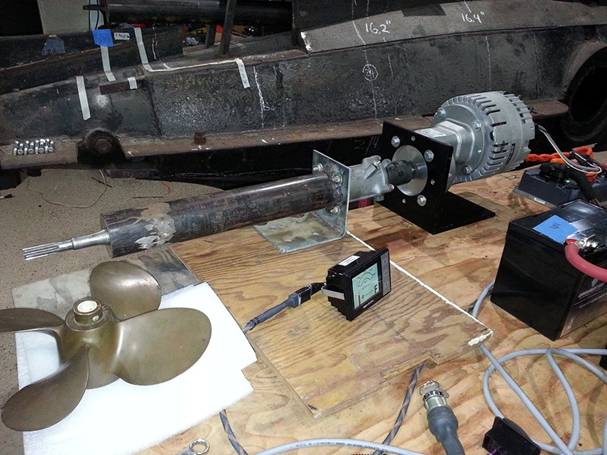

Tuesday, September 18, 2018: These

are the basic components for the propeller shaft. Two pillow blocks support a stainless shaft

with couplers; one mates to the motor and the other to the stuffing box. My only concern is that this shaft has a key

slot cut from end to end and I'm wondering what that variance in weight might

do when it's rotating at high speed.

Might have to swap this for a better shaft. I'll see what kind of vibration we get when

there's a motor turning it and decide then if it needs to be replaced. If not; this is what we'll be running.

Here it is lined up to measure

the length. For the first tests I'll

leave the end of the shaft from the JS-550 as is and turn a squirt drive in the

test tank because (1) that will be easiest and (2) we already have the squirt

drive. All I need to do is put a

hydrostatic load on the motor. The

JS-550 stuffing box contains bearings and seals and is watertight at moderate

depths. But after the shaft leaves the

pressure hull, it will also pass through a short pressure-compensated

bearing-and-seal case that I'll have to make.

That will ensure no water even gets to the stuffing box, let alone

inside it. So the already slim chances

of a propshaft leak into the pressure hull are

greatly diminished. When the tank

testing is done and we have to go to a propeller for the submarine, cutting

this shaft off at the start of the taper will give us the perfect length to put

a prop where it should be in the tail section.

Here's the JS-550 outbox, shaft,

and pump we'll be using for the first load tests of the motor. All newly rebuilt and ready go. The water-testing tank will get a hole in the

side that the stuffing box bolts onto.

Inside the tank, the pump will be securely bolted to a 2X6 screwed to

the tank walls, thus keeping the pump submerged. A big, heavy, glass table top will cover the

testing tank and we expect to see some real action in there!

The stuffing box is watertight

but again; I'm backing it up with an externally-mounted pressure-compensated

bearing case so water shouldn't even touch the box's aft end. Another important function this unit performs

is to act like a thrust bearing. Electric motors like mine aren't made to take

the axial loads usually imparted by a propeller so some kind of thrust bearing

is necessary to absorb that shock. In

this case, the stuffing box is bolted to the hull and will serve as a very

excellent thrust bearing.

Also today, we got a look at our

new gas analyzer that will be monitoring CO2 levels in the passenger compartment. Above that are the position indicators and

sensors we have for the rudder and dive planes.

Saturday, September 22, 2018:

The linear actuators arrived and have bench tested OK. They are slower than I thought, though. I can use them to operate remote valves in

the tailcone but for the controls I've decided to go

with power window motors and regulators.

The battery bears witness to how dusty it got in the shop before we did

the Epoxyshield floor. Nice and clean down there, now. J

Also today, we added a

controller heat sink and the Sevcon Clearview display to our motor order. The heatsink

protects the controller and this readout provides necessary information if we

want to alter the performance parameters of the motor. It will also come in handy when doing the

wet-tank tests of the drivetrain to determine RPM

under load and help us decide on the proper pitch for the propeller. Not inexpensive, but invaluable to the

project so it had to be.

The company I bought my shaft

couplers from only had SAE. The shaft is

M18 X 1.5 so I adapted an SAE coupler to Metric. There's a rubber "spider" between

couplers to absorb some shock. The only

problem here is, this shaft is threaded to work with a squirt-drive that turns

counter-clockwise and the Disney Nautilus prop turns standard. So after we finish the first tank-tests using

the hydrojet, I'll have to modify it for a right hand

propeller.The couplers come with four threaded

apertures with allen-type set screws. I'll chuck it up on the drill press, drill

through the coupler and shaft, and install a stainless pin as used in "pin

drive" outboards; an easy fix that solves a serious coupler-mating

problem.

And just for grins, I've decided

to make the battery box and aft system control panel look like the ElectroVulcanic Generator described in my novel, VULCANIUM

(The Secret of Captain Nemo and the Nautilus.) I recently learned there's a cool little

plasma sphere device that, when combined with a battery box built like the

first EVG mentioned in the book, will provide an interesting visual effect when

the boat is on display. So tonight I

bought one plus a USB battery pack to power it.

If none of this makes sense, read the book; available at Amazon and

Barns & Noble. (Shameless plug.)

https://www.amazon.com/dp/1478700009

My houseguest, Blackie La Goon,

has been crashing in the Vette and is openly opposed

to me working on it. No problemo, Blackie!

I'm focused on the submarine at this time, so it's all good. Won't be long before you're gonna have to find a new place to sleep, though. And stop playing the stereo so loud at night,

will ya? Sheesh! J

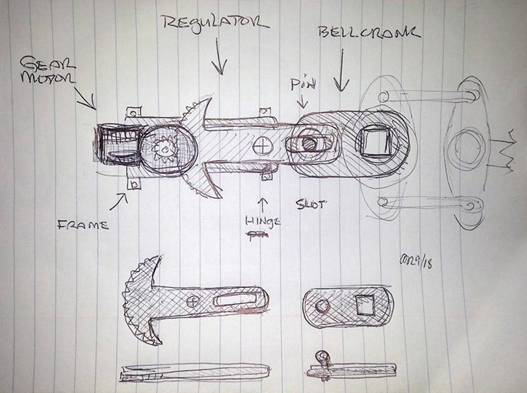

Monday, September 24, 2018: CONTROL

ACTUATORS: The linear actuators are out!

Too slow! Now, to actuate the

rudder and diveplane outshafts

and bellcranks, I've decided to use three of these

power window motor / regulator units from a Chevy truck. I'll cut the section bordered in red away

from the unnecessary metal; put a slot in the regulator blade where a ball-pin

on the outshaft bellcrank

will ride. Energizing the motor /

regulator will move the bellcrank, outshaft, external bellcranks and connecting rods of the control surfaces

themselves. Individual actuators on the

dive planes allows for pitch and / or roll control via a four-way joystick

switch.

I began the design work that

lead to the Nautilus Minisub in the mid-1980's. I have always done my R&D with drawings

like this. No CAD. This is all the visualization I need to know

it will work. I save the detailed

drawings until I'm making the actual part.

Many guys I've seen online live to create and share pretty computer

pictures of things they dream of building, and oftentimes that's as far as they

ever get. (I call that"Analysis paralysis.") I'm the

polar opposite of that. I develop the

design in my mind by actually thinking about it, rough sketch it on paper, and

build it out of steel. No time or need

for anything else.

Saturday, September 29, 2018:

CONTROL ACTUATORS: The power window motors work nicely! Perfect speed and plenty of torque. Checking the clearances in the tailcone near the propshaft

through-hull, existing plumbing for the ballast tanks, and the location of the

rudder through-hull packing gland; I might have to use a linkage (like the

drawing above) for the rudder.

For the dive planes, I can turn

that black regulator piece into the inner bellcrank

by replacing the round pivot hinge with a square hole to fit the end of the

dive plane through-hull shaft. That will

apply torque directly to the outshaft without any

additional bellcranks or linkages inside the

hull. Simpler is betterer. J

Wednesday, October 03, 2018:

PROPSHAFT: Been working on the drivetrain,

minus the motor. Looking into mounting

the motor as far aft as possible and measuring how that placement might

conflict with the existing ballast plumbing and proposed electric guidance

control mechanisms. Also seeing how that

affects weight and balance. So far, it

looks doable.

In this pic,

I am checking the positioning of the JS-550 propshaft

and gear box inside the tailcone where they will

eventually be bolted to the end cap.

There will be a bearing supporting the shaft at the end of that

wrap-around cylindrical motor mount where the original Minn

Kota trolling motor once resided. After

we've done the hydrostatic loading tests of the motor using a jetski squirt-drive; I'll cut the shaft off at the start of

the taper, put a 1/4" keyway in it and thread the end for a pin-drive

propeller and nut.

ELECTRIC COMPASS, CLOCK, AND

TEMP GAUGE: When I bought this

inexpensive electric compass, I had my doubts about it working inside an

all-steel double-hulled submarine and figured I could always put it in my

truck. BUT IT WORKS FINE! Accurate compass readings inside the

submarine and inside the shop to boot!

Didn't have this back in '91.

Sure will be nice to be able to actually navigate for a change. J

SALON WINDOW FAIRINGS: Years

ago, I began making and assembling the paper templates for copper pieces that

would comprise the salon window fairings.

Today, I'm getting ready to strip a lot of the exterior sheet metal so I

can perform major surgery on the pressure hull, but I don't want to lose what

I've done for the windows so far. So I'm

going to replace the lost (lower) paper templates and seal the shape with sheer

fiberglass cloth and resin. I might even

go as far as using Bondo to refine the shapes and

then glue on the cabochons as simulated rivet heads. When it's done I will build a box-frame

around it and pour rubber mold-making compound into it. That way, I will have a mold for making

fiberglass salon window fairings in 1:10th scale; lamp bezel, panel lines,

rivets and all. I decided long ago not

to make these out of copper because

insulating them from the steel (to avoid electrolysis in sea water) will

be very difficult to almost impossible.

I'll be using fiberglass and resin castings to detail other parts of the

exterior, so why not make the fairings out of the same stuff? No reason.

And I'll cast an extra to make a wall clock out of, too. J

Friday, October 12, 2018: THE MOTOR HAS ARRIVED! This is the ME1117 motor and Sevcon controller system I'll be running. 48 volts equals 6 HP continuous and 19 HP for

"full collision speed." Next,

I will assemble a battery pack and mount the entire drivetrain

on a test bench.

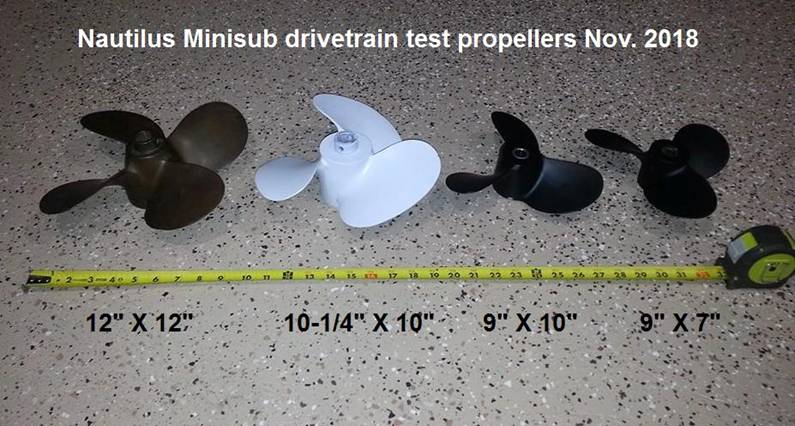

Tuesday, November 06, 2018: We now have the four propellers we'll test the drivetrain with.

We've covered a wide range of suitable diameters and pitches and will

check how the motor responds to each.

I'm pretty sure we're going to want a gear reduction box but first we'll

test these direct drive.

ALSO: I am building my own

5-bladed "Hammerhead" propeller (ala the Disney Nautilus) out of

steel. It will be functional but the

design isn't very efficient so it will mostly be for looks. When we want performace,

we'll be using something like what you see above.

Sunday, December 02, 2018: This morning I ordered a 2:1 GEAR REDUCTION for

the drivetrain.

Now, with the motor turning at a comfortable high end of about 4,000

RPM, figuring a 2:1 reduction and a 30% slip on the 12 X 12 prop, the

calculated boat speed is 15.9 MPH. In a

submarine of this size, type, and purpose; that should be plenty fast enough.

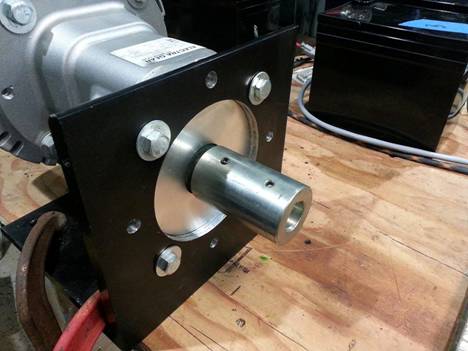

And this evening I made the

bushing that will adapt the splined end of our metric

JS-550 drive shaft to the SAE bore of our 12 X 12" four-bladed Michigan Wheel bronze propeller. I have the parts to adapt a shortened shaft

via a series of reducer couplings, but that's more complexity and weight and I

really don't want to have to cut this shaft if I don't absolutely have to.

The bushing is ground to the

proper ID and OD, and the ID flares to conform with the gradual shaft

expansion; making for a seamless transition without a "lip" or "

gap" where the coupler stops and the propshaft

begins.

With the prop and coupler

installed as seen in this picture, the propeller is staunchly attached and

true: zero play or wobble. It's a

"pin-drive" propeller so I'll drill the shaft to receive pins fore

and aft. Eventually I'll trim the end

of the shaft flush with the prop and install a hemispherical cap as seen on the

Disney Nautilus.

Mating the SAE propeller to the

Metric driveshaft was the last major engineering / fabricating obstacle to a

functional drivetrain. All I need now is the hardware to bolt

everything to an 8' 2X10 and then we're ready to start testing on the bench and

in the water tank.

Tuesday, January 29, 2019: Getting

the batteries shipped to Hawaii was a problem; getting them shipped via USPS undamaged

even moreso.

Of the four batteries I received one with a bent positive lug and

another with a cracked case, leaking acid.

Fortunately, the company will pay for return shipping and replace them

but going USPS is chancy.

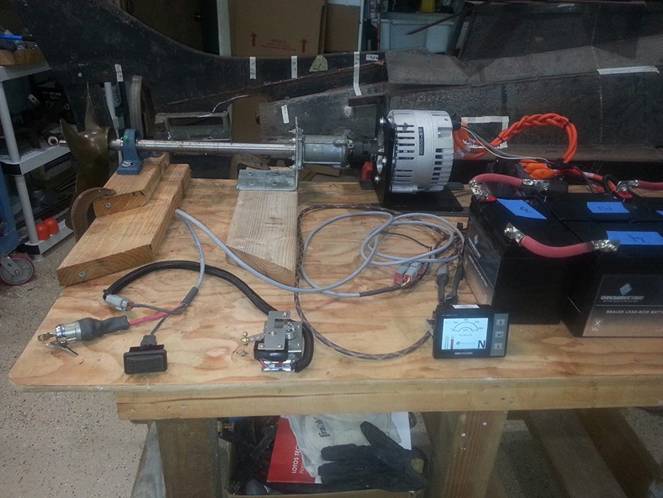

Yesterday I assembled the 48V

battery pack and bench-tested the motor for the first time. Everything works as expected.

Key Switch; Forward/Reverse Switch; Potentiometer; Servcon display; Battery Pack; Motor; Controller &

Harness; Kill Switch.

Operating unloaded motor at about 2,500 RPM. Not going to wind it out first time

through! J

Servcon display shows motor pulling 6 A @

49.8 V to generate about 3,200 RPM in Forward gear. Hour

meter still reads Zero; less than 1 minute.

Next, I'll direct-drive the

JS-550 bearing box and propshaft to spin the propeller

on the bench. Here I'm almost done

trimming the bearing box mounting plate and I'm blocking up the propeller

bearing with scrap lumber to get the shaft at the right height and level.

Propeller; Bearing; Prop shaft; JS-550 bearing box & coupler;

bearing box mounting plate; motor.

Bearing box mount made and installed; drivetrain

set up for bench test. Runs fine.

Turns the propshaft no sweat! Next, I make the tailcone

pressure-compensated shaft housing and frame mounts out of steel.

Wednesday, February 06, 2019:

One of the batteries had a crack in the case and was leaking acid. I sent CHROME BATTERY a few pics and the replacement battery is in the mail at this

time.

I was ready to buy a gear

reducer last October when an EMS engineer advised me to wait as they were

switching manufacturers in 2019. Today,

I'm glad I waited. The new gear reducers

are available as of day before yesterday; mine is bought and paid for and I'm

awaiting delivery with the understanding that there might be a manufacturer's

lag of seven days or so. The ones

available last year were from China and featured a cast iron case. These new ones are made in the USA, have

helical gears, and the case is aluminum.

And yesterday I welded the propshaft tube to the bearing box flange and set it up with

bearings fore and aft. Shaft turns

easily and smooth. The bearing box is

rated for 6,000 rpm and is said to be waterproof to one additional atmosphere

but I'm not relying on that. The propshaft tube will be PRESSURE COMPENSATED to keep water from reaching the bearing box

in the first place; a little insurance against water leakage at the propshaft

through-hull.

Saturday, February 09, 2019:

Propeller, shaft, compensated

housing, and watertight bearing box looking good so far.

Here's the tailcone

bulkhead I made 18 years ago; adapted to attach with bolts and a gasket to the

drilled-and-tapped tailcone boss. Waiting to put the center aperture (for the

tube) in it until the gear reducer arrives and direct measurements can be

made. At least a week there.

Found a 1/2" variance

between "level" on the port and starboard dive plane outshafts. Doesn't

affect hull or control symmetry but it's not right, either. So I've been rethinking the rudder and dive

plane through-hulls and decided to rebuild all three with bearings, seals, and

pressure compensation rather than the homemade packing-glands we dived

(successfully) back in 1991.

Also, we've always had problems

with the hatch design and placement. In

1991, it was heavy, loosely-hinged, and stood upright aft of the CG. The pilot had to drop into the aft

passenger's compartment, slide forward under the deck support, and pop up into

the cockpit. Not ergonomic at all.

For a long time I've worked on

designs where the wheelhouse section opens like a knight's visor; straight up

either forward or aft. But again,

putting that much weight that far off the CG and above the longitudinal

centerline just screams "instability!"

The answer? I'm building it to slide aft; something like

the canopy of an F-86 fighter jet aircraft.

(Not exactly like this; but similar.)

The section of cabin and wheelhouse over and around the pilot will slide

up and back over the "gills" without standing upright like a

sail. That should work well and look

pretty cool, too.

And for those who look for

faults: yes, I know it's rusty!

Construction of the NAUTILUS MINISUB began in 1985, she was proven in

1991, and has been sitting in storage ever since. This boat is all steel and going on 30 years

old. Submarines rust; that's a fact of

life. So this project is the restoration

of a vintage homebuilt submarine as much as anything else. Fortunately, there are such things as

sandblasters. J

Saturday, February 16, 2019: Still waiting on the gear reducer. Meanwhile, CHROME BATTERY replaced one unit

that was leaking acid; no problems. A

good company to deal with and I'll be using them again.

Received and bench-checked one

of two 12-volt actuated valves; it works fine.

A shipping error delayed the second valve; presently en route.

Also, decided to go with genuine

HARLEY DAVIDSON axles and bearings for my rudder and diveplane

through-hulls. My original shafts are

3/4" stainless and still look useable but I want to make three new boxes

from scratch. Harley axles and bearings

are also 3/4" and matched to closer tolerances than I'd get using my old

3/4" rudder shaft. Toss in a couple

seals, pressure-compensate the housing, and there ya

go.

New reproduction 1966 Harley Davidson heel bearings.

Also, I've decided on 12-volt

linear actuators for the rudders and diveplanes. Simple installation; zero adjustments or

maintenance; quiet and powerful; fast enough for the task depending on how it's

linked to the output shaft. The power

window motors would have worked but they are bulkier and space is at a premium

in the motor compartment. Of the two

choices, this turns out to be the best way to go.

Tuesday, February 26, 2019: Received the 2:1 gear reducer last night. Here's a pic of the

drivetrain with main components laid out in reference

to each other but not operational yet.

Looks like everything is going to fit into the hull. I've some small details to attend to and then

we will be bench-testing the drivetrain. Almost time to cut the hull and install this

into the submarine. J

Tuesday, March 12, 2019: Been acquiring parts and steel for the project. (More about that on The Clipboard page.

) Have made the decision to make riveted

panels (for the exterior detailing) out of 3/32" acrylic sheet with

hemispherical acrylic cabochons bonded on with Weld-On Acrylic Solvent ™.

Just did a test. Glued two 5mm

cabochons together to make a sphere.

Also glued one cabochon to a scrap of acrylic. The chem-welded

bond is very fast; gives you a chance to change your mind but sets with a

powerful grip in only moments.

Manufacturer's specs say in 18 hours the bond should be able to

withstand 2200 psi sheering force. The

acrylic sphere and test piece I made about an hour ago are so solid, I am

exerting all the force I can with my fingers and thumb yet can't break the bond

apart. And it's not even fully cured yet! Fantastic!

No more worries about rivet heads coming off in the water! This is a tremendous improvement over even

the best of adhesives we've tested so far.

Acrylic on acrylic with acrylic solvent is the way I will do the

exterior detailing on the Nautilus Minisub.

5mm acrylic cabochons; two chemically fused together as a sphere

and one bonded onto flat acrylic sheet with WELD ON acrylic solvent.

Tuesday, March 19, 2019: PROBLEM. Ran the drivetrain

on the bench as you see it in the picture below. Got an unpleasant surprise!

I ordered the motor so it would

spin the propeller clockwise, as the Disney Nautilus does. Then I ordered the gear reduction. At no point did anyone or anything advise me

that the gear reducer would make the shaft turn opposite the motor.

In my case it won't affect

performance because the motor is set to provide the same power output in

forward or reverse. But the indications

on the Sevcon display will be backwards: R when we're

going Forward and vice-versa. Not happy

about that at all. I don't see how a

company that provides electric motor components for vehicles can make a mistake

that blatant. But there it is. I'll deal with it.

Also, I don't really like the

jaw-type shaft couplers; too sloppy.

Seriously considering revamping

the drivetrain with a solid 7/8" to 1-1/8"

one-piece shaft adapter / coupler and 1-1/8" stainless shaft all the way

to the propeller. That will eliminate

the JS-550 bearing box and shaft; relying solely on the bearings and seals

within the pressure-compensated propshaft housing,

which I'll handcraft.

On the upside, this will

eliminate the friction of the JS-550 bearing box and allow me to change the

length of the propeller shaft to move the motor further forward toward the

center of gravity. That's a good thing

for this particular application.

Lemons and lemonade. J

Wednesday, March 20, 2019: PROBLEM SOLVED. This 7/8" stainless steel shaft

coupling is keyed 3/16" and mates perfectly with the output shaft of the

gear reducer. I'm obtaining a 36"

piece of 4140 chrome molly TGP stainless steel shafting; will cut keyway slots

in both ends and thread the last inch of one end 7/8" X 16 tpi. The shaft will

then mate perfectly with this coupling.

Stainless steel shaft coupling.

The threaded end of the shaft

will fit into this vintage 7/8" keyed, straight-bore brass propeller;

measuring 12" diameter and 13" pitch.

It will be secured with a shaft collar forward and a castellated

7/8" x 16 TPI nut, washer, and cotter pin aft. It's a three-blade; not a four like we had

before or a five like the Disney Nautilus has; but this should actually give

better performance than the one we had before and I'll deal with the cosmetic

issues of making a 5-bladed hammerhead prop after the boat's running. But even then; I expect the performance to be

miserable and will only use it for display.

For now, we'll be running this three-bladed prop.

12 X 13 brass propeller with 7/8" bore.

I've eliminated the JS-550 bearing

box and shaft. The pressure-compensated propshaft housing will be adapted to receive 7/8"

bearings and seals. Getting the new drivetrain running is only a matter of receiving the

materials and getting the keyways cut.

I think we're good to go again. J

Saturday, March 23, 2019: This is the "new" vintage 12 X 13 brass

prop in the condition we received it in; a little patina but the blades are

straight, no knicks, and it spins true. I won't have the 7/8" shaft until next

week but this prop has a 7/8" straight bore and fits nicely on the output

shaft of the gear reducer so I'm sure it will work.

12 x 13 brass propeller

Below is one of the Harley

Davidson axle bearings and the TGP 303 Stainless shafting I'll be using in the

control through-hulls. The bearing ID is

0.750" (3/4") and the shaft is turned, ground. and polished, tempered

and quenched, at 0.7495" OD. The

fit is suh-weet!!

J

3/4" control through-hull bearing and shaft examples.

Here's a look at that Harley

bearing sitting on the TGP stainless shaft; just in case you didn't believe me

about how close the fit is. No wobble

whatsoever. Me likey!!! J

TG&P guidance control output shaft and HARLEY DAVIDSON wheel

bearing.

Tuesday, March 26, 2019: Here's the

new 7/8" drivetrain components loosely assembled

on the bench. I could not be

happier. The fit is so close that you

have to "feel for it" like inserting a HARLEY DAVIDSON wrist pin into

a connecting rod. Absolutely beautiful. 4140 - 4142 Chrome Molly; 7/8 X 36 inches;

Quenched and Tempered to a Brinell hardness between

262 and 321; precisely Turned, Ground, and Polished to minus-five

ten-thousandths of an inch. A beautiful

piece of machined stainless steel.

For this picture, the flange

bearings are situated where they will be when the tailcone

mount and propeller shaft housing are complete.

The coupler, bearings, and propeller fit the shaft with similar

precision, as well.

I'll get some Brasso or Duraglit and

polish the brass propeller like a United States Marine's belt buckle. That chrome 7/8" x 24 tpi cap nut is from a HARLEY DAVIDSON springer. It's held on with plastic tape for this

staged photo.

Next, I take the shaft to a

machinist and have him thread one inch of one end 7/8" X 24tpi; cut a

2-1/4" long 3/16" keyway in that end; a 1-1/8" keyway in the

other and it's ready to go. I gotta fab some bench mounts for

the bearings and then we can test it dry.

And when I put that aft bearing

in the side of a water tank we can wet-test the drivetrain

and prop in real time. Gimme a week.

ADNOTE: Tonight I located the shaft, bearings, propeller, and cap nut in

their general positions and held the cap nut on with a piece of plastic packing

tape. Then I installed the rudder and checked to ensure

everything fits and the clearances are just fine. I think a 12" prop is about as big as I

can run without hitting the rudder linkages but I'm sure it will be more than

adequate.

Side view of propshaft, bearings,

propeller, and cap nut in position on the actual no-shit Nautilus Minisub. J

Alternative aft view

Back in 1991, that lightened

cylindrical mount carried the lower unit of a MINN KOTA 4HP trolling

motor. (And no, it didn't put out four

horsepower and nobody can understand why Minn Kota

called it that back in the day.) It also

serves as an anchor point for the hull longerons, as

well as a structural member connecting the horizontal and vertical fins. Parts of it will be retained for structural

integrity; others removed as necessary to provide clearance when installing the

propshaft housing.

For now, this mockup of actual

parts convinces me we aren't going to have any problems with this part of the

restoration. That's a big relief when

you've been waiting for parts in the mail.

Sometimes they don't always fit like you want them to. This time, everything fits beautifully. J

Wednesday, March 27, 2019: Here's a

simplified spec drawing I did to give the machinist an idea of what work I need

done. The threads are only

representative; I wasn't going to drive myself crazy trying to replicate 24 tpi. J

(1) Thread one end 7/8" X

24 tpi; (2) Cut a 2.25" 3/16" keyway in

that end, inboard of the threads; and

(3) cut a 1.25" 3/16" keyway in the opposite end. That's all I need.

Actually, I have the tools to

cut the keyways and thread the shaft by hand; I've done it before but it's a

lot of work on metal this hard and never as precise as what a machinist can

do. I want this to be perfect. So for this part of the job I'm farming it

out to a shop. That's a first for

me. In nineteen years, I have done every

lick of work this sub needed by hand; blacksmith style. I could do that to this shaft but that would

desecrate a beautifully-machined piece of steel and possibly put a weak link in

this vital component. No, it's

definitely machine-shop time! J

=MORE TO

FOLLOW=