REFURBISHING THE NAUTILUS MINISUB

PAGE FIVE

If

this is your first visit,

you

might want to scroll to the bottom and click PREVIOUS to access earlier

pages. There's four before this one.

~Otherwise~

SCROLL DOWN FOR THE LATEST

J

Wednesday, March 27, 2019: Refurbishing

4 became large and slow to load so

I've started Refurbishing 5.

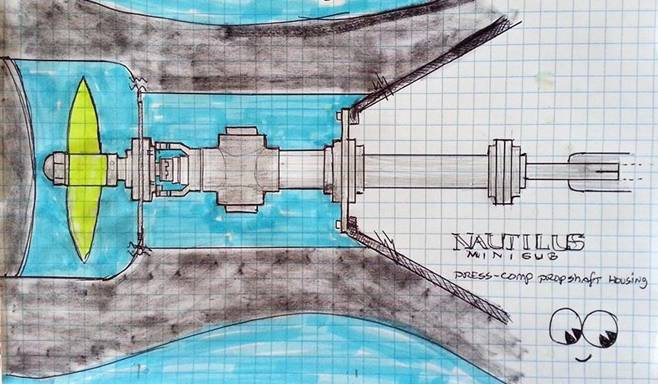

NAUTILUS MINISUB

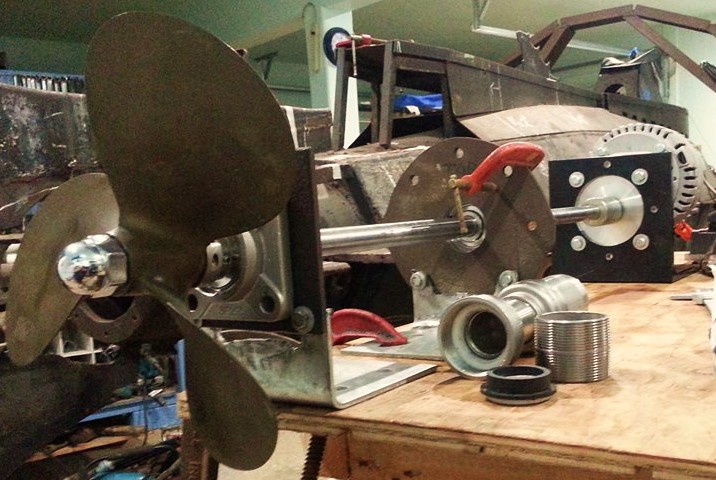

DRIVETRAIN: The blue cast-iron flange bearings shown on the previous page are

for setup and testing purposes only. For

the actual installation I bought a pair of these stainless steel flange

bearings. This way the entire drivetrain is stainless steel; bearings included. Better longevity in seawater than cast

iron.

7/8" ID Stainless

Steel four-bolt flange bearing.

Sunday, March 31, 2019:

Lots of work this past week; check THE CLIPBOARD for more info.

Last night I did this

diagram of the pressure compensated propeller shaft housing / manifold with a cutaway showing the

internal carbon-ceramic shaft seal.

Simple drawings like this help me in the design process. I'm not going to win any drafting

competitions but they help me check the fit of component parts before I order

them or they arrive by mail. This is

what we did before we had CAD, kids! J

The mottled black /

gray represents the submarine's pressure hull, fins, and rudder. The blue is water and the white is inside the

pressure hull; dry at 1 atmosphere pressure.

The prop is yellow because it's brass.

The cap nut and two of the flanges are chrome but everything shaded with

gray pencil is stainless steel.

(From left to right:

RUDDER; PROPSHAFT CAP NUT; WASHER; PROPELLER; COLLAR; SHAFT; BEARING; 1/4"

AFT BEARING MOUNTING PLATE; FLANGE; REDUCER BUSHING; INTERNAL SHAFT SEAL;

CUTAWAY BELL REDUCER; CLOSE NIPPLE; CROSS-TEE WITH REDUCER; NIPPLE; FLANGE;

1/4" BULKHEAD; FLANGE; NIPPLE; FLANGE; BEARING; SHAFT; COUPLING TO GEAR

REDUCER AND MOTOR.)

All of the parts for

this manifold are in the mail and arrive next week; should be able to start

assembly and testing soon. Film at eleven. J

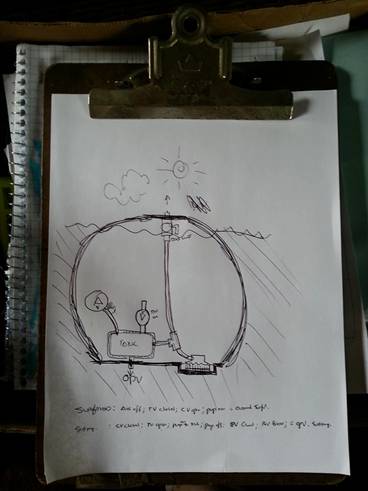

UPDATE, TODAY: Here's

another example of how a pad and pen aid my design process. This is my new bilge sump pump and tank

schematic. By controlling the valves, I

can either pump the bilge overboard when running surfaced; or to a storage tank

from whence it can be pressure-purged overboard while submerged. You don't have to get fancy. At this point; simple sketches like this are

all it takes.

Easily over 98% of

the prospective subbers I've talked to get what I

call "analysis paralysis";

they never get past the design phase.

For them, being a subber means being part of a

discussion group and sharing pictures and conjecture with others on that same

level. They are just playing with their

computers and they never get to the point of cutting steel. Analysis paralysis.

I'm exactly the

opposite. Simple concept schematics,

graph paper drawings, and templates are all I need to produce steel parts from

which I build submarines. I prefer to

spend minimal time drawing and maximum time fabricating. In contrast with others, I guess you could

say I have "fabrication motivation."

Works for me. J

Crude initial bilge pump

system concept diagram.

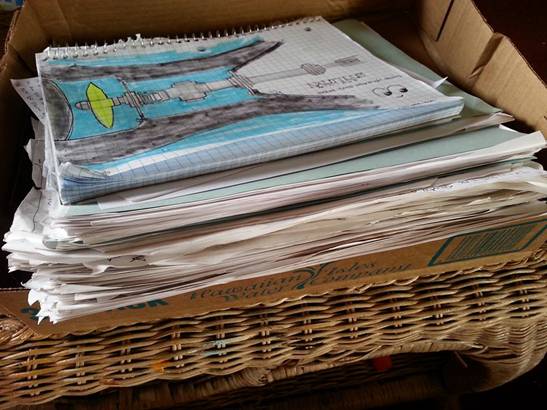

Even so, I still generate boxes of drawings

and research notes on a project like this; some basic and some more refined;

whatever's needed at the time. Here's a

look at what I've generated in the past several weeks working on the drivetrain, bench test setup, guidance control

through-hulls, 12V electrical accessories system, and now the bilge pumping

system. Every idea that occurred to

me; everything I need to buy, make, or otherwise acquire; and how I was going

to proceed is all documented in pages like these.

People say they

"can't imagine what it takes" to do something like this. For me, working under these conditions, this

is a big part of it.

Conceiving,

designing, and building a submarine is a lot of work, but I don't feel as

though I've "got" to do it; I feel like I "get" to do

it. When you love what you do; it's not

really work. J

R&D notes.

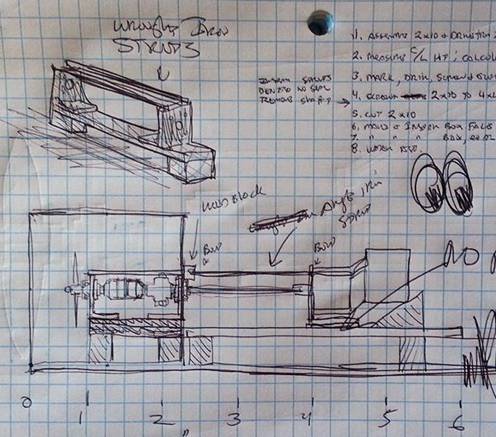

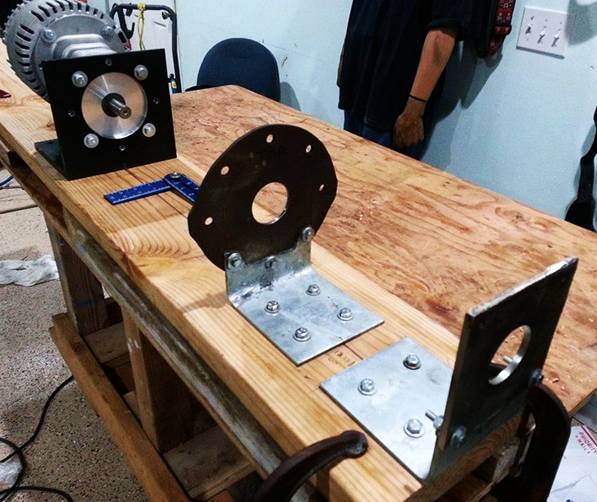

Wednesday, April 03, 2019: TEST BENCH: salvaged an old 3x9' sheet of

siding from which I'll cut a 2.5 x 6' base plate for the test bench; cleaned it

up and laid it out to dry. Also got the

10' 2X10" mounting board ready to go.

Still have to buy a 4x8' sheet of plywood to make the water tank.

DRIVETRAIN: The

propeller shaft went to the Machine shop on Monday and might be done tomorrow,

but you NEVER rush a machinist. J

Needed a few more

parts for the propshaft housing / manifold; they are

in the mail and some actually arrived today.

No unusual delays there.

Bought some heavy

duty brackets at Home Depot (to support the propshaft

bearings on the test bench) that were $30 each and the quality sucked. Taking them back for a refund. But first, I've used them as templates on a piece of 6"

x 6" square tube and I'll cut and drill my own brackets to fit the

bearings and flanges precisely.

The thing about

making these brackets is the propshaft height above

the 2x10" base board must be exactly the same from the motor through two

brackets and bearings, and to the propeller.

I tried guestimation and then got a better

idea. I cannibalized an old 7/8"

drill bit; chucked it up in the drivetrain shaft coupler;

positioned the template-marked bracket stock in front of the bit; and spun the

motor.

An old 7/8" drill

bit; shortened, sanded, and secured in the propshaft

coupler; to be used as a drill.

The intent was to

determine exactly where the center of the propshaft

will be when motor is mounted on its mount and the propshaft

bearings are mounted on 6" brackets atop a spacer made from a 1.5"

thick piece of 2x10" lumber.

ME1117 and Gear Reducer

driving 7/8" drill bit to mark centerline on mounting bracket stock.

In this pic you can see the guesstimation

marks I made with a scribe, using one of the bearings as a guide. Didn't measure anything; just eyeballed

it. The little round circle near the

center of the X is the actual centerpoint for the propshaft. (Drill

bit was junk.) I would have only been

off by a 16th of an inch, but when you're talking about something that's heavy and spinning at thousands of RPM; even

that small variance is unacceptable if I can prevent it.

"Best-guess"

scribe marks and actual center of drive train comparison.

Next, I'll put that

piece on the drill press and that's where the pilot bit of my carbide hole saw will go. Once I have drilled a nice 7/8" hole, I

can position the flange, bearing,and shaft to

precisely mark where all the bolt holes must go. Easy peasy! J

TEST BENCH WITH WATER

TANK: Here's a crude drawing of what I'm building: its

based on a 2X10; has a 2X2' water chamber around the prop and manifold. The MOON EYES are a "note to self"

to notice something on this page. Here,

it was that I'd decided to eliminate the 1/2" neoprene pads I've presently

used under the motor mount.

Basic schematic for test

bench / water tank; showing manifold, mounts, motor, and struts.

I know from past experience:

bolting everything down securely and minimizing chances for vibration are

critical. Not only will I not be using

rubber pads under the motor mount; I'm

making struts of angle iron that will be welded onto the top of the manifold

brackets and bolted from the forward bracket to the already drilled-and-tapped

motor mount. It's not enough for the

mounts to be fastened to the foundation; the tops of the mounts must be rigidly

connected to prevent them from flexing fore and aft under load, when things get

spinning and it all gets crazy. J

Saturday, April 06, 2019:

Got the basic drivetrain running on one bracket and

bearing last night. I used the old tailcone plate because it's already sized and drilled to

match the tailcone bulkhead boss. I roughed out a bracket to position the tailcone plate in alignment with the gear reducer output

shaft. Marked the center point and

drilled a 2" hole with my carbide hole saw. Worked fine.

I have to make one

more like this out of mild steel; about 5" square to serve as the

propeller bearing mounting bracket. Once

I have it all worked out, these old 3/16" mild steel parts will serve as

templates from which I will make final versions from 1/4" stainless steel.

3/16" mild steel

Nautilus Minisub tailcone

bulkhead; circa 1991.

Also, assembled the

propeller shaft housing / manifold and hung it in position with some wire to

check the fit. In this pic it's hand-tightened and still only 3/8" longer

than it needs to be to fit between the tailcone

bulkhead and propellershaft mounting brackets. I won't have any problem getting it to final

fit using a wrench.

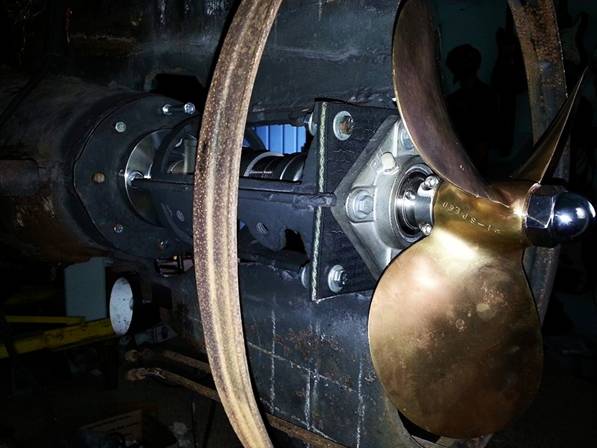

Stainless steel propshaft housing / manifold in position on Nautilus Minisub.

Next, I'll make a

prop bearing mounting plate; attach a bracket so it will bolt onto the bench;

size it next to the gear reducer output shaft, and mark the centerline. Cut a 2" hole around the center point;

insert the shaft, slide the bearing on the shaft up against the plate, mark the

bolt holes, and drill 'em. Once that's done I can bolt the brackets to

the bench; bolt in the manifold, insert the propshaft,

connect to the gear reducer, install the propeller and cap nut, and test it all

for clearance of rotary parts.

If it's okay, I

install the pump seal on the shaft, reassemble the drivetrain

with a temporary water jacket around the pump seal housing vent holes, and wet

test the seal. No leaks? We're ready to put it into the submarine. J

Monday, April 08, 2019: DRIVETRAIN: Had to redesign the propshaft manifold and ordered a new set of flanges over

the weekend.

Built an internal

seat for the carbon ceramic shaft seal; made it out of PVC parts of a swimming

pool pump hose, a rubber hose grommet; and a couple odd pieces of PVC.

Today I made a rudder

bearing mounting plate out of 3/16th mild steel; modified a piece of 6"

angle to support it on the testing bench; aligned it with the gear reducer

output shaft; and set up the basic drivetrain (motor,

gear reducer, L mount, shaft coupling, shaft, tailcone

bearing and mounting plate; propeller bearing and mounting plate; shaft collar;

propeller; cap nut) positioned and held together with a combination of bolts

and clamps.

It turns but I don't

dare run it until I get everything "trued-up and screwed down" as

they say. J

Didn't drill the

bearing mounting plates to receive the bearings yet; waiting until the new

manifold flanges arrive. I believe the

bearings and flanges share a common 4" bolt pattern and I'm hoping to get

by with only one set of four bolt holes per plate.

Here's a look at the propshaft sitting in the tailcone

and propeller support bearings. These

old steel parts will serve the bench testing process and become templates from

which I'll make better ones out of stainless steel.

Speaking of stainless

steel; those fittings in the lower right quadrant are the basis for the

manifold now. That white PVC material in

the bell serves as a watertight support for the mechanical shaft seal seat

holder. That black and white rubber

thing in front of the threaded nipple (like a lot of what I do) got cobbled

together from available hardware and parts of other devices adapted to my

purpose. That's been the theme of this

project since day one back in the 1980's.

No great big shop or supply source here; just a shadetree

mechanic making do with what's available.

J

Tuesday, April 09, 2019:

The propshaft manifold flanges don't arrive until

later this week; can't drill the bearing mounting plates until then. Meanwhile, I've laid out the lumber to make

the test bench (this is my workbench) and did a little cleanup work on that

vintage brass propeller. I'm not saying

it would pass Brass Inspection at MCRD San Diego, but ya

gotta admit it does look a little bit better. J

"Hi-Speed" 12

x 13 RH brass propeller

Wednesday, April 17, 2019:

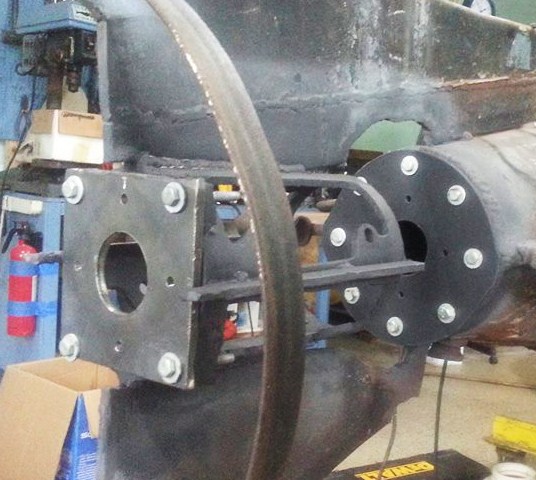

Went around in a couple circles getting the parts together for the propshaft manifold, but this is the final incarnation;

pretty much exactly as originally designed.

The bolt pattern on the bearings and flanges match so I can bolt them to

the tailcone bulkhead and propeller bearing bracket

via the same four shared holes; which is very fortunate (less work) for

me. J

Stainless steel

propeller shaft housing manifold.

Below is another view

of the manifold with the functional areas indicated and explained. A turbine-type high-speed carbon-ceramic

shaft seal is in the bell-chamber and the cross-T will comprise a

pressure-compensated chamber between the seal and the pressure hull / motor

compartment. Between the flanges and

bearings goes the 1/4" stainless steel tailcone

bulkhead and propeller bearing brackets, which bolt to the hull with rubber

gaskets. I have two 1-1/4 to 1/4"

NPT reducer bushings for the cross-T; to which the fittings for the air inlet

and one-way exhaust valve will fit, but they're not shown here. I (at least) need to shorten them for height

clearance and may actually have to weld them in.

I'm confident the

shaft seal will work but have some concerns about whether the pressure in the

air-compensated chamber will defeat the seal.

That's why we're going to put the drivetrain

together on a test bench; wrap a water jacket around the shaft seal chamber

(after we drill some vent holes in the center nipple); and test it for leaks

before it gets installed. If the seal is

as good as I think it will be; might not even need the pressure

compensation. We'll see when the time

comes.

L to R: Bearing; flange;

close 1-1/4" nipple; bell; close 2" nipple; bell; 1-1/4" close

nipple; cross-T; 3" nipple; flange; bearing.

And here's a pic of the manifold sitting in the tailcone

of the submarine. This isn't precise but

it shows about where it will sit when the drivetrain

is operational. And for our new

visitors: yes, the submarine is rusty and dusty. It's all surface rust and that's why they

have sand blasters. J

Propshaft manifold positioned in tailcone / motor-mount area of NAUTILUS MINISUB.

I think the visual

contrast between the rusty steel and the stainless manifold is interesting:

depicts this as a vintage (old) homebuilt submersible being refurbished with

new parts and technologies. That's kind

of what this refurbishment is all about.

The NAUTILUS MINISUB is an old warhorse being reborn. When complete, all that "crud of

ages" will be blasted off and she'll receive a new exterior covering of

acrylic resin, acrylic cabochons (rivets), and acrylic enamel paint to

compliment all the beautiful new stuff being installed.

UPDATE TODAY: Here's

better looks at the manifold. I think

this exemplifies the spirit with which I've approached creative technologies

right from the start: "Adapt what's available to accomplish what you

need."

This is a fairly

sophisticated device of my own invention: a propeller shaft housing that combineds a turbine

shaft seal with pressure compensation. Most people would need to have something like

this made for them and/or machined from scratch. I found a way to do it using available

hardware and things laying around my shop.

This is what you call backyard submarine boatyard ingenuity, folks. That's what I'm all about. J

Side elevation view:

NAUTILUS MINISUB propeller shaft manifold.

The fasteners look

long but will come out just right when there's a 1/4" stainless steel

mounting plate and rubber gasket between the outer bearings and flanges. The reducer bushings in the cross-T go down

to 1/4" NPT to accommodate the airline and exhaust valve fittings. The entire assembly (including the plates

that mount it to the submarine) are all stainless steel so there will be

virtually no chance of rust contaminating the mechanical seal or bearings.

Planform view: NAUTILUS MINISUB propeller

shaft manifold.

I want to get the

reducer bushing bosses down flush with the top and bottom of the cross-T. If it gets too tight trying to thread it down

that far; I'll either shorten it and redress the threads or weld the hex head

on. Getting very close to having the drivetrain running on the bench with a functional water

test of the shaft seal. Progress! J

Sunday, April 21, 2019:

As of tonight I have the stainless steel propeller shaft bearing mounting plate

and mild steel tailcone bulkhead on brackets, aligned on and bolted to a 2X10, and I'm

about to secure the motor. Next, I

temporarily install the propellershaft, mark the

holes for the bearing / flange mounting hardware; drill those eight holes and

then I am ready to assemble for bench testing.

Stainless steel

propeller bearing mounting plate. Still

a little cleanup to do.

Assembling and aligning

the motor bracket, tailcone bracket, and propeller

mounting bracket on the bench for marking and drilling of bearing / flange bolt

holes.

That little blue tool

is called an OMNISQUARE and was very

helpful in measuring and aligning the brackets on the 2X10.

While the propeller

bearing mounting plate is now stainless steel (to keep rust out of the

mechanical shaft seal chamber) I'll be using the old (mild steel) tailcone bulkhead because (1) I already have it and it's

ready to go; (2) it doesn't touch the shaft seal wet chamber so it can't add

rust to that area; and (3) it connects to the hull (which is mild steel anyway)

so it doesn't make any difference to the system whether this part is mild or

stainless steel. I'll sand blast it,

treat it for rust, and paint it with acrylic enamel before it goes into service

on the submarine.

UPDATE: Tonight I got very close to having it

properly aligned so I can the holes for the bearing mount hardware. Still have a little tweaking to do to the

middle bracket. Working on it. That's the propeller shaft housing manifold

laying next to it. J

Prop shaft in bearing

blocks to motor on bench prior to marking and drilling bearing fastener holes.

Monday, April 22, 2019: Got the bearings and flanges aligned and

marked on their respective mounting plates.

A little white spraypaint did the trick. Comes right off with Brake Clean. After taking this pic

I drilled eight holes and testfit these parts on the

submarine.

Bearings, flanges, tailcone bulkhead and propeller bearing mounting plate.

EVENING UPDATE: And this

is as far as I got with it today.

Everything's positioned in the submarine's empennage and seems like it's

going to be okay. I've got to shorten

the original motor mount at the white chalk line to locate the propeller

correctly in the fin cutout, but that was expected.

Propshaft and manifold installed for alignment

check.

Here's a video where I'm spinning the

prop by hand with the manifold in place.

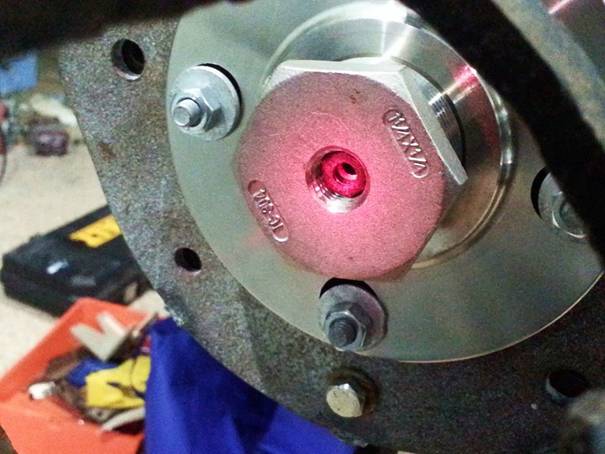

Wednesday, April 24, 2019:

Check this out. Did a low-tech laser

alignment test on the propshaft bearings and it came

out pretty much spot-on. First of all, the

laser emitter isn't exactly aligned in the pointer housing, so I had to aim

it. Also, the pointer housing is smaller

than the 7/8" bearing aperture, so I wrapped it in a paper towel and

aligned it with a piece of Gorilla Tape. High tech, eh? J

Aft view: laser pointer

in propshaft bearing; aimed at tailcone

bearing.

Laser pointer in propshaft bearing.

To center the tailcone bearing and flange AMAP, I put a reducer in the

flange and a small nut inside the reducer.

The bright spot of the laser beam passed through the nuts' center hole

and that red glow is scattered residual light bouncing off the reducer.

Residual laser light on tailcone bearing reducer.

This pic was taken at an angle from inside the

starboard salon window frame. As Rube

Goldberg as this test- device was, it still projected a laser dot to the

forward end of the pressure hull that was only off the longitudinal centerline

by an inch or so. That's pretty straight

for a rig like this and tells me that (1) my initial measurements and calculations

were good; and (2) there shouldn't be any difficulty doing the final (precise)

alignment of the propeller shaft when it comes time to install the motor.

Laser dot falls nearly

dead center at forward end of pressure hull.

Next, I have to buy

all the correct hardware and fasteners; shorten the original MK motor mount to

properly locate the propeller bearing mounting plate; get the manifold adjusted

to the right length; and install the shaft seal. Then it will be time to do a wet bench test

of the seals' watertight integrity.

Coming right along and so far no insurmountable problems! AHEAD… FULL!!! J

UPDATE: Today I used the

torch and grinder to remove about 1/2" of steel from the point in the

empennage where the propeller bearing mounting plate resides. Now the propshaft

cap nut clears the rudder. Needs a

little fine adjustment but the dirty work is done; for today, anyway. ARGH!

J

Propeller and rudder in

position with adequate clearance.

Saturday, April 27, 2019:

I decided I wanted a bit more clearance between the rudder and cap nut. Did a couple days surgery with the torch, big

and little Makita grinders, a carbide-tipped die grinder, and a Dremel. My new

OMNISQUARE tool came in handy repeatedly and works great! A big help!

Still, it was more

art than science as I gradually worked down to the desired level; stopping

along the way to mark high points with paint and squaring the surface by

grinding. All done by eyeball and

measurement.

Propeller bearing

mounting plate situated and squared with tailcone

bearing plate.

At this point, the

forward surface of the propeller bearing mounting plate is squared with aft

surface of the tailcone bearing mounting plate. Checked at eight locations around the prop

plate's circumference, we have a uniform distance of 12-3/8 inches. This was important to ensure the propeller

shaft passes through both bearings uniformly, and to determine the actual

length of the propeller shaft housing manifold.

12.375" all the way around or very close to it.

Here's a look at the

submarine's empennage mounts, cleaned up and ready to go. The tailcone plate

is mild steel; the propeller bearing plate is stainless steel.

stainless steel prop bearing

plate; original motor mount, shortened and squared; tailcone

bearing plate.

Next, I'll set it up

on the bench, assemble the manifold and shaft seal, and wet test them. If the seal is okay, then it's time to

install the drivetrain in the pressure hull. J

UPDATE TODAY: I'm questioning whether or not I should

assemble on the bench to wet-test the shaft seal; only to have to disassemble

and reassemble it all again in the boat.

I've already functionally tested the drivetrain

dry so I know it works. I'm pretty sure

I can install a mechanical shaft seal right the first time. I'm gonna go ahead

and install everything but the motor in the submarine. I can wet-test the seal by turning the shaft

in any of a number of ways not dependent on the actual motor. If the seal works, then I'll cut a dorsal

access hatch in the tailcone and install the motor,

guidance controls, and ballast system servo valves. This ought to save me at least a week or

more. Me likey! It shall be so! J

LAST GASP TONIGHT: VIDEO: Did a

test installation of the propshaft and housing

assembly into the submarine's original motor mount area. Everything lines up correctly and turns

nicely. I haven't lubed the bearings yet

but I'm pretty sure that "squeak" is a well-timed coqui

frog barking outside the open window a couple feet away. They've been going all night. J

So apparently this is

going to work and setting up for a wet bench test of the shaft seal would be a

waste of time.

Now I need to buy

eight 5/16th and four 1/4-20 fastener combos of the right length. And I've been waiting on a replacement for a

SS close nipple that arrived galled and useless; on the way and should be here

in a few days.

I made a neoprene

gasket years ago when I made the tailcone plate. I'm going to make another for the tailcone flange.

It's pretty thick stuff; I'll have to subtract its thickness from the

manifold length. But it will give us a

heavy duty "industrial grade" watertight rubber mount between the propshaft housing flange & bearing and the pressure

hull. Good seal and I'm expecting some

noise dampening. Could rubber mount the

propeller bearing mounting plate too, for that matter.

After I get it

running on the motor using hardware store fasteners, I'm going to weld some

1/4-20 threaded connectors in place and switch the cap screws over to stainless

steel button-head Allens. That way I'll be able to take off the

propeller bearing mounting plate without having to remove the outer hull plates

so I can get a backup wrench in there.

Sunday, April 28, 2019: Made the crude prototype of a reinforced

neoprene rubber mounting plate to replace the stainless steel propeller bearing

mounting plate I've used until now.

Concept seems feasible; I can see some improvements that can be

made. But this will help to inhibit the

migration of vibration and noise between the drivetrain

and the hull. Basically, the advantages

are shock absorption and sound deadening.

Since the tailcone cover plate, bearing, and flange will also be

rubber-mounted; this part of the drivetrain is rigged

for fairly quiet running. J

Tuesday, April 30, 2019:

I've decided not to do a preliminary installation and test of the shaft seal

because (1) it's not necessary; (2) I could damage the seal setting it up for a

"rehearsal"; and (3) I'll have to do it all again after the motor's

installed. I do believe I can install a

mechanical shaft seal right the first time.

I've done enough "spin tests" to be confident of how everything

is lining up and the numbers say it will fit.

I am proceeding to install the motor.

Yellow square marks

motor compartment hatch aperture.

Tape marks areas to be

cut.

As of last night and

this morning, I've got the hatch cut laid out and parts tape-marked for the

torch or plasma cutter. Gonna have rounded corners.

I'll scribe lines into the steel with an electric engraving tool and

remove the tape before I start cutting.

This will be the

first hull surgery of this magnitude since I first built the submarine. It's kind of an awesome feeling; what I'm

about to do. If I screw-up here, I could

wreck the boat. I'll just have to make

sure I don't screw-up, right? J

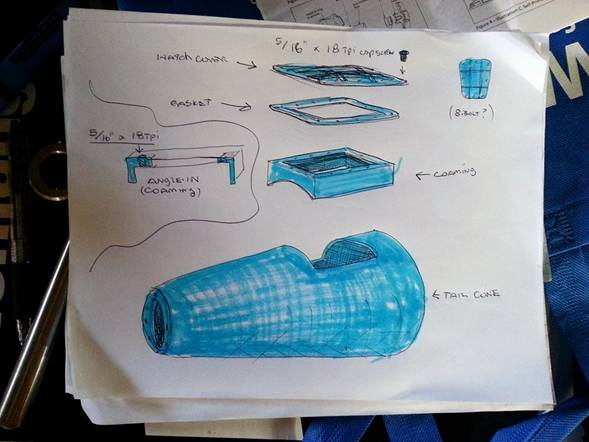

Wednesday, May 01, 2019: I'm not into computer design, 3D printing, or

any of that. I am totally "by

hand" and "blacksmith style"; but that's all I've ever

needed. Here's a simple concept sketch

of how the hatch will be built. (And I usually don't go into this much

detail. J )

Nautilus Minisub motor compartment hatch concept sketch.

The vertical sides of

the angle-iron coaming will also serve as the walls

at the top of the aft ballast tanks. The

"L" of the angle iron will face inboard; serving as a flat flange for

the hatch cover and gasket. The flange

fastener holes will be drilled and tapped for 5/16" cap screws.

I was thinking of

using a flat hatch with a 12-bolt pattern.

But then I thought about welding on some external stiffeners for

strength and when I drew it out I realized all I'd need is eight bolts.

Now all I have to do

is measure the boat, make cardboard templates, cut the steel, and weld it

up.

For me, it's all

about minimal graphics and maximal fabrication.

I avoid "analysis paralysis" by getting right into making

parts ASAP. Works for me. J

Thursday, May 02, 2019: I spend a lot of time looking at the sub and

thinking about what I'm doing to it; new ideas arise that way. It was the same with my motorcycle. I'd ride it to the waterfront end of First

Street in Benicia and kick back in the shade enjoying a cold beer while

contemplating what I wanted to do to it next.

I remember one time some girls drove by and yelled, "Park it and

look at it!" LOL! Nobody wants to understand. J

Anyway, right now

with the submarine's 3/16" steel tailcone plate

and the 2X2" bell chamber nipple; the manifold is exactly 1/8" too

long to fit. I can rectify that when I

tighten the nipple into the seal chamber bell and if that doesn't work I have

ordered a 2" close nipple that will

give me all the room I need, lengthwise.

But then, there's the

added thickness of the flange and tailcone-plate

gaskets; another half inch all together.

That would make the assembly 5/8" too long.

I was thinking

about how to handle that problem when it

occurred to me; why not make the tailcone plate out

of reinforced rubber? It's only

1/16" thicker than the steel; plus it eliminates the thickness of both

gaskets. I can make that fit without

bending it.

But what about depth

pressure defeating a rubber tailcone plate? We're talking about making part of the

pressure hull out of rubber and that sounds kinda

crazy the first time you hear it. Okay,

maybe the second. But it makes sense

when you think about it.

The diameter of the

flange is only about 1/16th of an inch smaller than the aperture inside the

drilled and threaded tailcone boss; and the square

bearing housing takes up most of the room on the other side. The tailcone boss

supports the entire outer periphery of the plate and if I use wide washers (or

a single toroidal band of sheetmetal

drilled with eight holes) almost all of

the rubber surface will be backed-up by steel.

And that which isn't

directly supported is too thick, hard, and reinforced to pass through any tiny

(crack-like) gap that might exist; even at far greater depths and pressures

than this boat will ever be asked to endure.

Considering the way

the assembly is built and attached to the submarine, and the strength

characteristics of the material I'm using; I do believe a rubber tailcone plate is feasible and will greatly reduce

perceived vibration and noise migrating from the drivetrain

to the hull. Worth a try, anyway.

White (painted) steel tailcone cover plate; black neoprene tailcone

cover plate; propshaft manifold with mechanical shaft

seal and pressure compensation; tailcone bearing.

So today I laid out

and cut a rubber tailcone plate from 1/4"

fiber-reinforced neoprene that was once part of a conveyor belt at the local

sugar mill; traced the metal cover with an ink pen and cut it out with a

box-cutter.

TECH TIP: Cutting

rubber like this can be extremely difficult because it has a very high drag

coefficient. Getting a bare blade

through it is a fight every step of the way.

But use a little DAWN Detergent

or the like to lubricate the rubber and your blade will slide through much

easier.

Then I laid the plate

on the cutout rubber facsimile and shot a little white paint to re-mark the

holes. And if I use the metal plate, the

inside of the motor compartment is going to be white anyway; so all's well.

After the paint

dries, it's time to put holes in it.

I've got some punches I use for making bolt holes in the collar gaskets for deep sea

diving helmets; I'll try that. If not,

there's always that funky little Ryobi drill press I bought. It ain't a

workhorse but I'm pretty sure it can cut holes in rubber. Maybe.

Worth a try, anyway. J

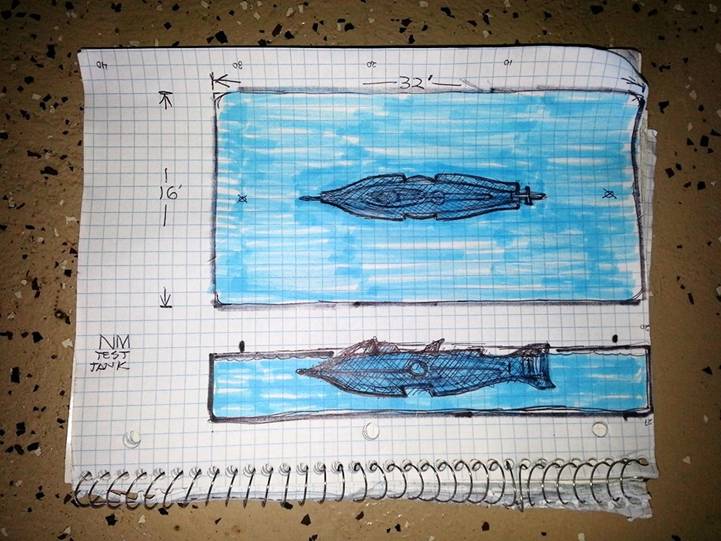

Friday, May 03, 2019: When the time comes to test the Nautilus Minisub, I could drive it to the harbor. Or I could ask my friend (who owns a crane)

to put it in our 32 x 16 x 4.5' pool. If

I rig a "dog run" cable (with stops) lengthwise over the pool from

our shipping container to our forklift, I can drive the boat about 10 feet

without any chance of poking a hole in the liner. With foam rubber boots on the keel, we can

submerge safely on ballast, too. And if

I center and secure the boat to something ashore in a manner where it can't

possibly break loose (steel cables to my 5 ton forklift) I don't see any reason

we can't push the drivetrain to cruising speed and

higher.

(And as I write that, I'm sitting here visualizing what it will be like

to be in the sub or the immediate area, when that boat is in the center of our

pool with the motor cranked up to collision speed full. I get stoked just thinking about it.)

I drew this with it

sitting on my lap; didn't try too hard to get the lines straight but you get

the idea, right? J

There will be plenty

of room for the sub and crew in the pool.

This way I can get everything dialed in and working right before I take

it to the ocean. Plus, if I ever want to

train anyone how to pilot the Nautilus Minisub, this

would be a safe and convenient way to do it.

Not to mention the fact that it's going to be an outrageously fun pool

toy to play with. J

Lynn Regan tends

Christine "Steenie" Nelson as she submerges

in a homemade air-supplied diving helmet for the first time in her life. The smile says it all. J

In Benicia back in

the 1980's, we were letting our friends play with homemade rebreathers

made from soda bottles; and air-supplied diving helmets made from an ink-pen

display Lynn salvaged from the dumpster at Longs

Drugs. From those humble (but fun!)

beginnings, we've gone to training people how to dive a 20,000 Leagues rig in

our pool and soon we'll be able to operate the submarine in there, too. Wow.

That even blows MY mind.

LOL! J

MORE TO FOLLOW…