REFURBISHING THE NAUTILUS MINISUB

PAGE SIX

"The tools and equipment are gathered; the shop is

prepared; and we have the wherewithal to proceed. The actual work of refurbishing the Nautilus

begins now."

Pat Regan, October 2020

In the midst of the Covid-19 pandemic

lockdown, we worked on the salon window fairings and prepared the shop for

major hull surgery.

We bench-tested the drivetrain again.

Several months of indoor storage hadn't affected it at all.

This full-scale functional mockup

"proof of concept" device helped us develop how the new hatch opens

and closes.

This thin (still flexible) fiberglass

shell will become a rigid plug for sand-cast aluminum fairings.

We removed delicate items from the

work area, put the dolly up on blocks aligned with the shop, and checked for

straight and level.

Here I've cut the tail fin assembly

off in preparation for installing the new drivetrain.

The dolly was then removed and set

aside.

The tailcone

pivot bearing assembly was installed on the submarine.

Positioned for welding. The bracket top welds directly to the hoist

vertical post; the sides were gusseted to fill the gaps.

On the

rollers with tailcone pivot bracket welded to the old

hoist. I will cut those rusted-out

casters off and weld in a couple long pieces

of angle iron to connect the hoist with the rollers. Don't want their relative positions shifting

in the midst of hull surgery. But after

that, we're ready to roll.

After

measuring at various points to ensure the Nautilus was straight up and level;

an old carpenter's square placed flush with the floor and the keel indicates

exactly 90 degrees vertical with no visible gaps between the surfaces and the

square. She's straight, level, and

aligned with the shop.

That last

part is more important to accuracy than some might think. Knowing she sits straight and level, plumb at

the keel, means accurate vertical measurements can be made all along the length

of the boat from end to end; critical to aligning the new drivetrain

and external aspects of the hull and superstructure.

Plus,

anything that might affect visual perception (like a crooked alignment in the

room) must be abated or eliminated.

That's what I've tried to do here.

Once I've

added steel to stabilize the jig floor pattern; I'll (1) remove the upper

superstructure framing and plating to access the pressure hull; (2) cut an

aperture in the upper tailcone and ballast tanks for

a motor-compartment access hatch; (3) remove the guidance control through-hull

bosses from the tailcone; and (4) remove the entire

upper cabin structure from the pressure hull.

That will complete the dissection of the submarine; after that, we start

building again.

Tuesday, October 13, 2020: Been working on removing the

superstructure. Tried using our new Lotos plasma cutter; it has no problem with 1/4" mild

steel but 1/2" is about all it can handle.

The frame for the submarine's superstructure is 5/8" square rod

(solid; not tube) and in some places that's gusseted with 1/4 X 1/2" bar;

from which the Lotos produced a lot of dross. So I fired up the Oxy-Acetylene torch and

made quick work of it. Tomorrow I'll

take off the rest of the superstructure to get to the pressure hull in the

cabin area.

Wednesday, October 14, 2020 3:22 AM: I continued working and completed the removal of the

superstructure. Here, for the first time

in thirty years: the pressure hull's naviform cabin

structure (originally designed for my earlier project, the HYPERSUB) is

visible. Next, I'll cut a hatch aperture

for the motor compartment and remove the cabin structure from the pressure

hull.

Saturday, October 17, 2020:

Since last time, I got her as level fore and aft as I can. I shimmed the hoist about 1/2-inch and now

the center of the propshaft and the ramming spur are

both exactly 39.75" above the floor; sitting on the roller.

I also spent

some time measuring where the cabin cuts will be made.

To ensure

that everything is as straight as I can make it, I've decided to build a wooden

alignment jig (a rectangular framework of lumber) around the boat. That's more expense and takes more time; but

I do believe the results will be worth it.

The steel

that's been exposed to the elements shows surface rust but nothing serious at

this gauge.

The ballast

tanks were prepped with Salt-Gone and the plumbing has remained sealed since

1991; we expect the interior to look good and will know when I cut the motor

compartment aperture.

The ballast

tank exteriors showed a little surface rust and were treated with rust / primer

converter and coated with a layer of fiberglass resin back around 1999

IIRC. There's been considerable intergranular corrosion and exfoliation taking place under

the resin as evidenced by the "zits" all over the hull; and I do

expect that can be cleaned up.

The pressure

hull exterior shows no corrosion at all.

It all looks nice and smooth and I was glad to see that after all these

years.

Oh, and

since this is the first time in a long time that the pressure hull has been

seen, let me preclude the inevitable observations with an explanation.

Yes, I know

flat sides and angular surfaces are inferior to arched, rounded surfaces when

it comes to making submarine pressure hulls.

There's

reasons for everything. Got it under

control. I know what I'm doing.

She's

reinforced and the design has already made seven successful dives.

This is not

a deep-diving boat and we operate under secure conditions following an agenda

in accord with the boat's capabilities.

Basically,

she's a purpose-built manned submersible stunt vehicle; and for that role she's

exactly as she needs to be.

The

forthcoming modification lowers the deck one inch; accurizes

the "wheelhouse" design; turns the aft cabin hatch into a bolt-on;

and configures the cockpit hatch to slide up and aft like the canopy on an

F-86; for easy pilot access. But it will

still be shaped generally like the original; shown above.

Sunday, October 18,

2020: Jus' fer grins. "The

Nautilus Engine Hoist." This is the

device with which I will drop the new motor into the Nautilus and I thought it

should be appropriately dressed for the occasion. J

66" Nautilus by

Jim Key

Tuesday, October 27, 2020: Nothing to write home about; been

hampered by an ear-and-throat problem last week and haven't made a lot of

progress. Didn't want folks to think I

was a slacker so I'm posting this. J

Decided

against the wooden framing jig; I can do the same thing with two custom-made

steel brackets, some cable and a few turnbuckles. Easier and cheaper. Glad the downtime gave me an opportunity to

think about it; saved me from making a costly and time-consuming mistake.

Here's a

couple random scenes around the shop: the removed superstructure and a candid

view taken while I was labeling all the removed hull plates for temporary

storage.

The little

biker was my wife's idea; came with a bike replica from Harley Davidson in

about 1/8th scale. He'd be a little less

than eight feet tall if my 1/10th scale Nautilus was lifesize.

J

Thursday, October 29, 2020:

HULL REINFORCEMENTS.

I want to

add some reinforcement rings to the pressure hull. Most folks would farm this out to a metalfab shop but I've got to find a way to do it myself;

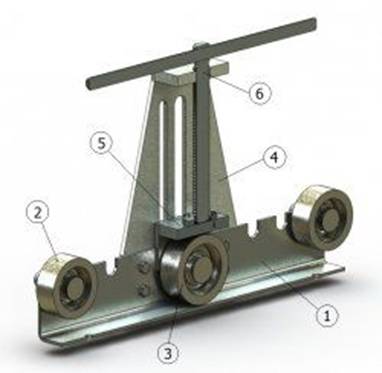

so I'm designing and building a ring roller.

This pic is an example of what one might look like but the

actual design I'm presently developing is different. I'll be using a jack (scissors or bottle) to

provide the bending force; scratch-building it out of old scrap steel, shafts,

and bearings already in the shop from other projects. But they all work basically the same.

IMPROVEMENTS

TO MANEUVERABILITY:

Basically,

the Nautilus steers like a train. I want

to add some 24-volt ROV thrusters (like these) sideways in the bow and stern so

I can pivot the boat around its vertical axis.

These are reversible, dry to 200 meters, and generate about 20 pounds of

thrust: plenty enough to do the job.

As always,

the modification is complicated by the need to conceal this within the Nautilus

design. At this point, it looks like

these will be transversely-mounted and hidden within the superstructure; the

ends covered by spring-loaded "flaps" that open with thrust flow; or

automatically close to conceal the aperture when the motors are inoperative.

TO BE CONTINUED…